Effluent or Water Treatment Processes (WTP/ETP)

Criteria

of Water: Criteria are requirements that a water source must satisfy

in order to be used for a particular purpose. In other terms, criteria are specifications

indicating the minimum quality level that the water must have to support a predefined

use. Criteria are important in defining the characteristics of inlet water streams.

Criteria

of Water: Criteria are requirements that a water source must satisfy

in order to be used for a particular purpose. In other terms, criteria are specifications

indicating the minimum quality level that the water must have to support a predefined

use. Criteria are important in defining the characteristics of inlet water streams.Different criteria exist for different water uses:

Water

Use

Water

Quality Criteria

Drinking Water : Microbial count, pH, color, turbidity,Organic content, pH, toxic compounds,dissolved oxygen, Temperature, Salt, Metals, etc.

Industrial : pH, suspended solids, temperature, dissolved oxygen.

Swimming,

fishing : Similar to drinking

water criteria but not as stringent.

Cooling, navigation : Floating solids, suspended solids and pH.

Cooling, navigation : Floating solids, suspended solids and pH.

Standards of Water: Standards

are the characteristics that the waste water must satisfy to be lawfully discharged

to a receiving body of water or to a POTW. In other terms standards refer to

the quality of the outlet

water, after its intended use.

Criteria vs. Standards of

water:

Types of Discharges of

Industrial Wastewaters:

1. Direct industrial

discharges to freshwater or saltwater streams.

2. Industrial discharges to a

Publicly Owned Treatment Works (POTW).

Classification of

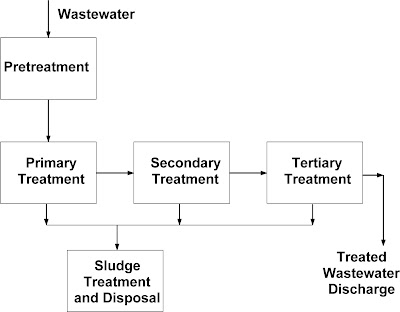

Wastewater Treatments Processes:

Pretreatment: Pretreatment usually

refers to any treatment the wastewater is subjected to before entering a conventional wastewater treatment plant, such as a POTW. Pretreatment typically involves operations connected to

separation of very coarse or easily

Pretreatment of industrial

wastewaters commonly refers to any treatment required to make the water

acceptable for discharge to a POTW.

It is common practice to classify wastewater treatment

processes in three categories:

i) Primary treatment: Primary treatment pertains to

the removal of easily separable materials such as oils, floating solids, or quickly

settling solids, and the preparation of the

ii) Secondary treatment: Secondary treatment is

typically the most important part of the process, and is used primarily to

remove the bulk of the suspended solids, organic materials (both hazardous and

non-hazardous), and other soluble materials. Biological treatment constitutes

the process of choice during secondary treatment of wastewater.

iii) Tertiary treatment: Tertiary treatment, involving

processes such as sand filtration,

reverse osmosis, adsorption,

and electro dialysis, is used (if necessary) to remove any

Sludge

treatment and disposal: Sludge treatment and disposal includes all the operations

connected with the concentration, stabilization, and final disposal of the

semi-solid sludge produced during the primary, secondary and tertiary

treatments. Sludge treatment and disposal includes operations such as gravity

thickening, air flotation, aerobic and anaerobic digestion, chemical or heat

stabilization, centrifugation, drying, filtration, incineration, wet oxidation,

and disposal in landfill or on soil.

Typical Activated Sludge Treatment Plant:

Unit Operations in Wastewater Treatment:

Industrial

wastewaters typically contain a number of heavy metals, halogenated organic

compounds, and other priority pollutants. Therefore, industrial facilities must

process their wastewaters before discharging to either a body of water (under

NPDES permit) or a POTW.

Typically,

these pollutants are removed from the wastewater using a variety of pretreatment processes, especially physical and chemical processes.

Examples

include coagulation, flocculation precipitation, sedimentation, filtration, ion

exchange, air stripping, membrane separation activated carbon adsorption, wet

oxidation and photochemical oxidation.

Example

of Physical-Chemical Wastewater Treatment Process:

Typical

Physical-Chemical Treatment Plant:

Physical

Separation Processes:

Activated carbon adsorption

Distillation

Electrolytic recovery

Hydrolysis

Ion exchange

Solvent extraction

Membrane separation technologies

Air stripping and steam stripping

Thin film evaporation

Freeze-crystallization

Operations

Involved in the Removal of Suspended Solid in Wastewaters:

Screening

and comminution

Grit

removal

Sedimentation

Floatation

Filtration

and centrifugation

Coagulation/sedimentation

Operations

Involved in the Removal of Biodegradable Material in Wastewaters:

Activated

sludge treatment

Trickling filters

Rotating biological contactors (RBC)

Aerated lagoons

Anaerobic lagoons

Facultative lagoons

Anaerobic treatment

Operations

Involved in the Removal of VOCs in Wastewaters:

Adsorption

Absorption

Air

stripping

Condensation

Freezing

Incineration

Combustion

Operations

Involved in the Removal of Nitrogen in Wastewaters:

Biological

nitrogen utilization in activated sludge process

Biological

nitrification and denitrification

Air stripping of ammonia

Chlorination

Adsorption

Operations

Involved in the Removal of Phosphorus in Wastewaters:

Biological

phosphorus utilization in activated sludge process

Chemical

additions (metal salts or polymers)

Lime

addition

Biological/chemical

treatment

Operations

Involved in the Removal of Organic Priority Pollutants in Wastewaters:

Aerobic

biological treatment

Anaerobic

biological treatment

Biological

treatment/activated carbon adsorption (PACT)

Adsorption

Chemical

oxidation

Operations

Involved in the Removal of Heavy Metals and Dissolved Inorganic Solids in

Wastewaters:

Chemical

oxidation/reduction and precipitation

Ion

exchange

Reverse

osmosis

Ultrafiltration

Electrodialysis

Example

of Heavy Metal Remova :

Example

of Organic Chemical Removal:

Classification

of Hazardous Waste Treatment Processes:

Physical

Chemical

Biological

(Disposal)

Physical

and Chemical Processes for Hazardous Waste Treatment:

Filtration and separation

Chemical precipitation

Photolysis

Chemical oxidation and reduction

Dehalogenation

Ozonation

Evaporation

Solidification and stabilization

Biological

Processes for Hazardous Waste Treatment:

Aerobic processes

Anaerobic

digestion

Composting of industrial wastes

Land treatment of industrial wastes

Biodegradation of environmental pollutants

Enzymatic systems

Thermal

Processes for Hazardous Waste Treatment:

Liquid injection incineration

Rotary kilns

Fluidized-bed

thermal oxidation

Hazardous wastes as fuel for burners

Cement kilns

Wet oxidation

Pyrolisis processes

Oceanic incineration

Molten glass processes

Deep shaft wet air oxidation

Supercritical water extraction

Plasma systems

Mobile thermal treatment systems

Catalytic incineration

Infectious waste incineration

Land

Storage and Disposal of Hazardous Wastes:

Surface impoundment

Disposal in mines and sand domes

Aboveground disposal

Hazardous waste landfilling

Subsurface injection of liquid hazardous wastes

Additional

Information and Examples on Wastewater and Waste Treatment Processes

References:

Droste,

R. L., 1997, Theory and Practice of Water and Wastewater

Treatment,

John Wiley & Sons, New York

Eckenfelder,

W. W., Jr., 1989, Industrial Water Pollution Control,

LaGrega,

M. D., Buckingham, P. L., Evans, J. C., 1994, Hazardous

Waste

Management, McGraw-Hill , New York

Metcalf

& Eddy, 1991, Wastewater Engineering: Treatment, Disposal,

and

Reuse, McGraw-Hill , New York

Sundstrom,

D. W. and Klei, H. E., 1979, Wastewater Treatment,

Prentice

Hall, Englewood

Wentz,

C. W., 1995, Hazardous Waste Management, 2nd edition, McGraw-Hill, New

York, pp. 153 - 248.